Here at Auburn Bearing, we offer a complete line of standard thrust bearings, including 12 ball bearing series and 1 cylindrical roller bearing series. Many of these bearing series feature Auburn’s exclusive V-groove raceway, which was designed specifically for the purpose of reducing rolling friction.

The Auburn bearing styles that incorporate this raceway have the added advantage of being able to carry radial loads equal to 25% of their thrust load capacity. All of our bearings are proudly made in the USA and can be customized to meet the special needs of your application.

To view or download our catalog as a PDF, please click here.

Jump to Section:

Inch Thrust Bearings | Metric Thrust Bearings | Thin Section Bearings (Aurotek) | Bearing & Component Interchanges | Parametric Bearing Search

Inch Thrust Bearings:

-

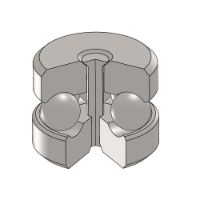

T-100 Banded Thrust Ball Bearing Series

-

T-101 Thrust Ball Bearing Series

-

T-114 Thrust Ball Bearing Series

-

T-114RG Thrust Ball Bearing Series

-

MT-114RG Mounted Thrust Ball Bearing Series

-

T-170 Thrust Ball Bearing Series

-

T-200RG Thrust Ball Bearing Series

-

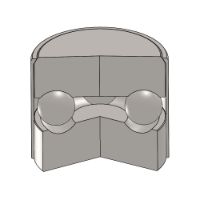

SC-100 Thrust Ball Bearing Series

-

SC-114RG Thrust Ball Bearing Series

-

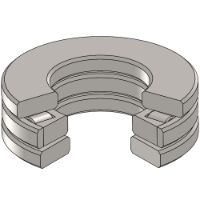

AE Cylindrical Thrust Roller Bearing Series