Documents / Articles / Information Removed from Government Websites

We manufacture custom bearings, thrust bearings, and thin section bearings in the USA from one piece to thousands.

We are proud of our 120+ years of experience, quality and service. Our sales, engineering and production people have a long history with this company. Auburn Bearing & Manufacturing is not just a place to work; it is a part of our lives. They take pride in their work and we take pride in them.

We are fortunate to have affiliations with many fine companies that understand the extra effort required to do a job well. We would like to take this opportunity to thank them for helping us to achieve the Auburn Advantage.

On August 18, 2006, the Auburn Ball Bearing product line was purchased from M. D. Knowlton Company by Fairport Products and moved to 4 Route 350, Macedon, NY 14502. On June 10, 2013, Fairport Products and Auburn Ball Bearing became one company and is now known as Auburn Bearing & Manufacturing.

We are proud to continue the tradition of Manufacturing Thrust Bearings started in 1898.

Learn more about us here.

Breathing New Life into Bearings: How We Modified a Garlock DU Bearing

As well as manufacturing, Auburn Bearing & Mfg. has a long history of modifying other companies’ bearings. Below is an example of a Garlock DU bearing modified to meet the customer’s print. These bearings were originally designed in the 1950s and used in...

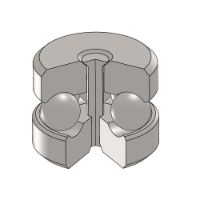

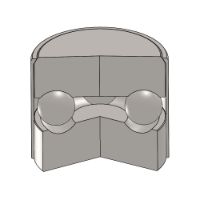

New at Auburn Bearing: Stock & Custom R Series Thrust Ball Retainers

Auburn Bearing & Mfg. is pleased to announce that we are stocking and manufacturing the R Series Thrust Ball Retainers! One-piece design Stamped steel cages with chrome steel balls CLICK HERE TO EXPLORE THE R SERIES » We also offer custom ball retainers made from:...

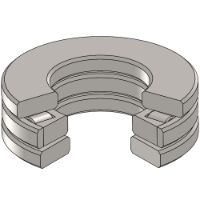

Enhanced Machinery Performance with Auburn’s 51100 Bearings

Auburn Bearing & Mfg. is excited to introduce you to our latest innovation in precision engineering: the 51100 Bearing Series. Elevate your machinery’s performance to new heights with our high-quality bearings designed for unmatched durability, reliability, and...

Thrust Bearing styles

-

51100 Metric Thrust Ball Bearing Series

-

51200 Metric Thrust Ball Bearing Series

-

R Series Thrust Ball Retainer

-

T-100 Banded Thrust Ball Bearing Series

-

T-101 Thrust Ball Bearing Series

-

T-114 Thrust Ball Bearing Series

-

T-114RG Thrust Ball Bearing Series

-

MT-114RG Mounted Thrust Ball Bearing Series

-

T-170 Thrust Ball Bearing Series

-

T-200RG Thrust Ball Bearing Series

-

SC-100 Thrust Ball Bearing Series

-

SC-114RG Thrust Ball Bearing Series

-

AE Cylindrical Thrust Roller Bearing Series

-

2900 Metric Thrust Ball Bearing Series

-

F Metric Thrust Ball Bearing Series

-

FM Metric Thrust Ball Bearing Series

From SOME of our many enthusiastic customers:

“Frankly, I don’t pay much attention to these bearings any longer. With the new design, it has gone from a headache to a non-issue. Therefore, I would rate this a great success.

These bearings have proven to be far superior to our current option. Machine consistency is the biggest improvement. Also, the inability for a maintenance person to assemble the old 3-piece bearing incorrectly.

The custom solution was by far the better solution to anything I could find on the market. I will certainly reach out to Auburn for future custom issues.”

“We are very pleased to have found Auburn Bearing & Manufacturing to make bearings for a 1916 Fiat aircraft engine, used in a speedboat that we were restoring.

The bearings we needed were obsolete and Auburn Bearing & Manufacturing made the replacement bearings from old, used, worn, bad samples.

One bearing was very unique in that it was a combination Ball Thrust and Ball Radial Bearing with two rows of balls! Fortunately for us, Auburn Bearing made our restoration easy and successful!”

“Auburn has very high-quality bearings and substantial technical expertise in materials. As a material scientist it was wonderful to have the level of engineering expertise Auburn offers for specialty and custom applications.

It has been a pleasure working with Auburn on sourcing our new product. We will specify Auburn products again without hesitation and I have recommended Auburn several times to current and former clients.

American manufacturing needs American components. Thank you Auburn!”

“Auburn Bearing and Manufacturing has always been able to assist with the Strong Museum’s mission to preserve classic arcade games and pinball machines.

One hurdle that comes with collecting rare and vintage games is finding sources for parts. Partnering with Auburn Bearing and Manufacturing has facilitated the preservation of many games that otherwise wouldn’t be able to be restored.

They are always enthusiastic to provide solutions for our unique requests. Having a local source for custom work like this is invaluable for the museum’s mission of conserving and maintaining coin-op machines for our guests and researchers to use and enjoy.”