Why do bearing companies list all those bearings in their catalogs that are no longer stocked or produced?

History is the main reason. If you think about how a bearing product line came about, most were a customer’s idea born out of a need, “I need a bearing with an ID of X, an OD of X, and a Width of X, with a load capacity of X; it’s like bearing XYZ but lighter or heavier duty.” So a bearing manufacturer would design the bearing and start producing it. Eventually other customers would want one, or one just slightly different, thus giving rise to the engineering and marketing of a “series” of bearings. Over the years some sizes proved to be in high demand and others not so much.

As bearing manufacturers grew, they had to justify their investment in high production equipment. The production threshold of what to produce and in what volume became higher and higher. Part numbers for the less produced, lower demand bearing sizes, remained in the catalog. Production lead times for these bearings sizes became longer.

We at Auburn Bearing & Manufacturing have part numbers in our catalog that have not been made in 20 years but it’s not a problem if you want one of these items. Why, you ask? Our production equipment is designed for low to medium volume quantities with a high mix of part numbers. This allows us to have shorter production lead and run times.

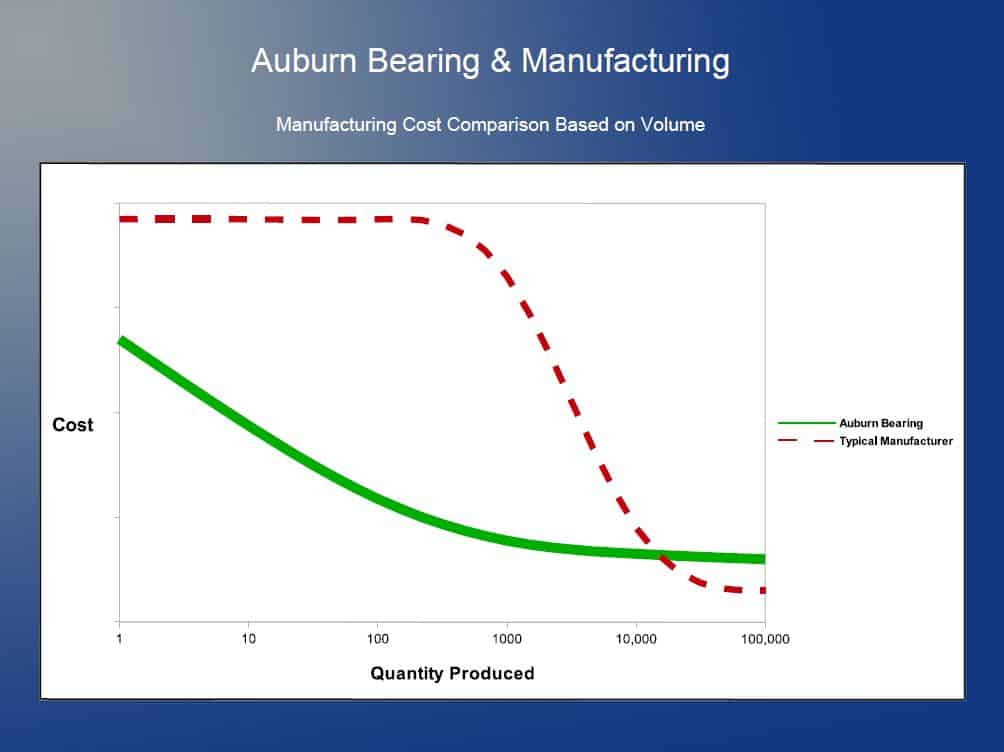

Below is a cost vs. volume curve that shows how 1 piece costs more than 10 pieces and how the curve is flatter.

Yes, this type of production method is more expensive at higher volumes than traditional high volume bearing production, but it is very cost effective for low to medium volume production. This type of production offer shorter lead times.

So the next time you need a custom thrust bearing or need only a few pieces of an obsolete thrust bearing, give us a call. We service this niche every day!