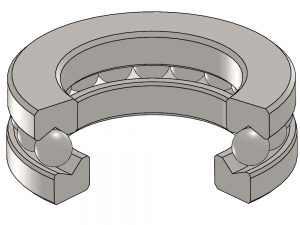

T-101 Thrust Ball Bearing Series

The Auburn Open Style T-101 Thrust Ball Bearing is designed to make the best possible use of the limited amount of bearing space that may be available. T-101 consists of two hardened steel races with a full complement of balls.

When preloaded and installed so as to be held by the outside diameter B, the “V” grooved raceways enable this series to carry radial loads equal to 25% of its thrust load capacity, while decreasing the amount of friction created by a full contact round groove design. The open style design of this bearing will allow the maximum circulation of lubricating products.

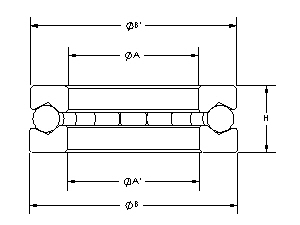

The T-101 Thrust Ball Bearing is available in inch dimensions from 0.5″ through 5.313″ bore, 1.125″ through 9.25″ OD, and 0.625″ through 3″ height.

| Bearing Number | Bore (A) | OD (B) | Height (H) | Stock? | |

|---|---|---|---|---|---|

| T-101-1 | 0.5 | 1.125 | 0.625 | No | Details |

| T-101-2 | 0.625 | 1.313 | 0.625 | Yes | Details |

| T-101-3 | 0.75 | 1.438 | 0.688 | No | Details |

| T-101-4 | 0.875 | 1.5 | 0.688 | Yes | Details |

| T-101-5 | 0.875 | 1.75 | 0.688 | Yes | Details |

| T-101-6 | 0.938 | 1.938 | 0.813 | No | Details |

| T-101-7 | 1 | 1.938 | 0.813 | No | Details |

| T-101-8 | 1.063 | 1.938 | 0.75 | No | Details |

| T-101-9 | 1.063 | 2.125 | 0.75 | No | Details |

| T-101-10 | 1.125 | 2.125 | 0.813 | No | Details |

| T-101-11 | 1.25 | 2.344 | 0.938 | No | Details |

| T-101-13 | 1.438 | 2.438 | 0.938 | No | Details |

| T-101-15 | 1.5 | 2.531 | 0.938 | No | Details |

| T-101-16 | 1.688 | 2.688 | 0.813 | No | Details |

| T-101-19 | 1.813 | 2.938 | 0.938 | No | Details |

| T-101-21 | 1.688 | 3.125 | 1.125 | No | Details |

| T-101-22 | 1.813 | 3.125 | 1.125 | No | Details |

| T-101-23 | 1.875 | 3.125 | 1.188 | No | Details |

| T-101-24 | 1.938 | 2.938 | 1 | No | Details |

| T-101-25 | 1.938 | 3.188 | 1.188 | No | Details |

| T-101-26 | 2 | 3.188 | 1.188 | No | Details |

| T-101-27 | 2.063 | 3.188 | 1.125 | No | Details |

| T-101-28 | 2.188 | 3.25 | 1 | No | Details |

| T-101-30 | 1.938 | 3.438 | 1.25 | No | Details |

| T-101-31 | 2.438 | 3.5 | 1.125 | No | Details |

| T-101-32 | 2.5 | 3.5 | 1.25 | No | Details |

| T-101-33 | 2.313 | 3.625 | 1.25 | No | Details |

| T-101-34 | 2.125 | 3.719 | 0.813 | No | Details |

| T-101-38 | 2.813 | 4.5 | 1.5 | No | Details |

| T-101-40 | 3.188 | 5.375 | 1.5 | No | Details |

| T-101-41 | 3.438 | 5.5 | 1.5 | No | Details |

| T-101-42 | 4.125 | 5.875 | 1.5 | No | Details |

| T-101-44 | 5.125 | 7 | 1.5 | No | Details |

| T-101-48 | 1.063 | 2.438 | 1 | No | Details |

| T-101-49 | 1.313 | 2.688 | 1.125 | No | Details |

| T-101-50 | 1.563 | 2.938 | 1.188 | No | Details |

| T-101-51 | 1.813 | 3.188 | 1.125 | Yes | Details |

| T-101-52 | 2.125 | 3.75 | 1.25 | No | Details |

| T-101-53 | 2.438 | 3.938 | 1.5 | No | Details |

| T-101-57 | 3.438 | 5.5 | 1.75 | No | Details |

| T-101-62 | 4.688 | 7.25 | 2.375 | No | Details |

| T-101-63 | 4.938 | 7.5 | 2.375 | No | Details |

| T-101-67 | 5.938 | 9.25 | 3 | No | Details |

Other Info & Resources

Mounting Instructions: Generally installed with the fitted bore A centered on the shaft and rotating with it, the clearance bore A’ seats against a fixed part of the machine and remains stationary. If installed in a recess, a clearance of 1/8″ or more should be left around the outside diameter B and B’, in case the shaft wears in it’s journal bearings. If this should happen the clearance you allowed on the outside diameter will prevent the balls from wedging. When used to carry a combination radial and thrust load, diameter B requires a snug fit in the housing.

Downloads:

T-101 Series Datsheet

T-101 Series Catalog Page

Related Articles:

Auburn “V” Groove Reduces Friction & Drag in Thrust Bearings