T-170 Thrust Ball Bearing Series

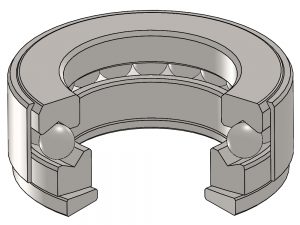

The T-170 Thrust Ball Bearing with spherical seat is enclosed and is recommended for use in exposed locations where protection from foreign matter is required and where an alignment problem between shaft and housing exists.

This bearing series is not recommended where alignment constantly changes. The two washers and balls being held together as a unit by the outside sleeve plus the aligning washer compose one complete bearing.

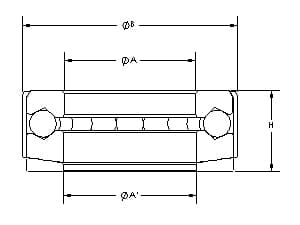

The T-170 Thrust Ball Bearing is available in inch dimensions from 0.5″ through 6.5″ bore, 1.188″ through 8.75″ OD, and 0.5″ through 2″ height.

T-170s are not regularly scheduled for production. Consult Auburn Bearing & Manufacturing for availability.

| Bearing Number | Bore (A) | OD (B) | Height (H) | |

|---|---|---|---|---|

| T-170-1/2 | 0.500 | 1.188 | 0.500 | Details |

| T-170-1 | 0.500 | 1.063 | 0.750 | Details |

| T-170-2 | 0.625 | 1.375 | 0.813 | Details |

| T-170-3 | 0.750 | 1.500 | 0.875 | Details |

| T-170-4 | 0.875 | 1.813 | 0.875 | Details |

| T-170-5 | 0.938 | 2.000 | 1.063 | Details |

| T-170-6 | 0.938 | 2.000 | 0.875 | Details |

| T-170-7 | 1.000 | 2.000 | 1.063 | Details |

| T-170-8 | 1.000 | 2.000 | 0.938 | Details |

| T-170-9 | 1.063 | 2.000 | 0.938 | Details |

| T-170-10 | 1.063 | 2.188 | 1.063 | Details |

| T-170-11 | 1.125 | 2.188 | 1.125 | Details |

| T-170-12 | 1.188 | 2.188 | 0.938 | Details |

| T-170-13 | 1.250 | 2.188 | 0.938 | Details |

| T-170-14 | 1.188 | 2.406 | 1.188 | Details |

| T-170-15 | 1.250 | 2.406 | 1.188 | Details |

| T-170-16 | 1.313 | 2.406 | 1.188 | Details |

| T-170-17 | 1.313 | 2.406 | 0.938 | Details |

| T-170-17A | 1.375 | 2.406 | 0.938 | Details |

| T-170-18 | 1.438 | 2.406 | 0.938 | Details |

| T-170-19 | 1.438 | 2.500 | 1.188 | Details |

| T-170-19A | 1.375 | 2.500 | 1.188 | Details |

| T-170-20 | 1.438 | 2.594 | 1.188 | Details |

| T-170-21 | 1.500 | 2.594 | 0.938 | Details |

| T-170-22 | 1.500 | 2.594 | 1.188 | Details |

| T-170-23 | 1.625 | 2.594 | 0.938 | Details |

| T-170-24 | 1.688 | 2.594 | 0.938 | Details |

| T-170-25 | 1.813 | 2.750 | 0.875 | Details |

| T-170-26 | 1.688 | 2.750 | 1.000 | Details |

| T-170-27 | 1.875 | 2.750 | 1.000 | Details |

| T-170-28 | 1.563 | 2.750 | 1.250 | Details |

| T-170-29 | 1.625 | 3.000 | 1.500 | Details |

| T-170-30 | 1.938 | 3.000 | 1.063 | Details |

| T-170-31 | 2.000 | 3.000 | 1.063 | Details |

| T-170-32 | 1.688 | 3.188 | 1.438 | Details |

| T-170-33 | 2.188 | 3.188 | 1.000 | Details |

| T-170-34 | 1.750 | 3.188 | 1.438 | Details |

| T-170-35 | 2.250 | 3.250 | 1.063 | Details |

| T-170-36 | 2.313 | 3.250 | 1.000 | Details |

| T-170-37 | 1.938 | 3.250 | 1.500 | Details |

| T-170-38 | 2.000 | 3.250 | 1.500 | Details |

| T-170-39 | 2.188 | 3.875 | 1.563 | Details |

| T-170-40 | 2.250 | 3.875 | 1.563 | Details |

| T-170-41 | 2.438 | 4.000 | 1.625 | Details |

| T-170-41A | 1.938 | 4.000 | 2.000 | Details |

| T-170-42 | 2.500 | 4.000 | 1.625 | Details |

| T-170-43 | 2.938 | 4.625 | 1.875 | Details |

| T-170-43A | 2.750 | 4.625 | 1.875 | Details |

| T-170-44 | 3.000 | 4.625 | 1.875 | Details |

| T-170-45 | 3.000 | 4.625 | 1.375 | Details |

| T-170-46 | 2.438 | 4.625 | 2.063 | Details |

| T-170-47 | 3.438 | 5.000 | 1.375 | Details |

| T-170-48 | 2.188 | 5.000 | 2.875 | Details |

| T-170-49 | 4.500 | 6.250 | 1.875 | Details |

| T-170-50 | 3.438 | 6.250 | 2.625 | Details |

| T-170-51 | 3.000 | 6.250 | 3.625 | Details |

| T-170-52 | 4.000 | 6.875 | 2.625 | Details |

| T-170-53 | 4.438 | 6.875 | 2.875 | Details |

| T-170-54 | 5.000 | 7.000 | 1.750 | Details |

| T-170-56 | 6.500 | 8.750 | 2.000 | Details |

Other Info & Resources

Mounting Instructions: The Enclosed Style T-170 Ball Thrust Bearing is generally installed so that the washer having bore A is centered by the shaft and rotates with it. The washer with the sleeve attached to it and having clearance bore A’ and its aligning washer seat against a fixed part of the machine and are stationary. If installed in a recess, a clearance of one-eighth inch, or more, should be left around outside diameter B so that if the shaft should wear in its journal bearings, the thrust bearing will be free to follow without cramping or wedging the balls.

Downloads:

T-170 Series Datsheet

T-170 Series Catalog Page

Related Articles:

Auburn “V” Groove Reduces Friction & Drag in Thrust Bearings